Sash Window Glossary & Jargon

How to use this glossary

The world of sash windows comes with its own set of terms. This page gives you clear, one-line explanations so you know exactly what each part is called. Use the diagram for quick reference, or scroll through the A–Z list below. If you need tailored guidance for your project, we’re only a message away.

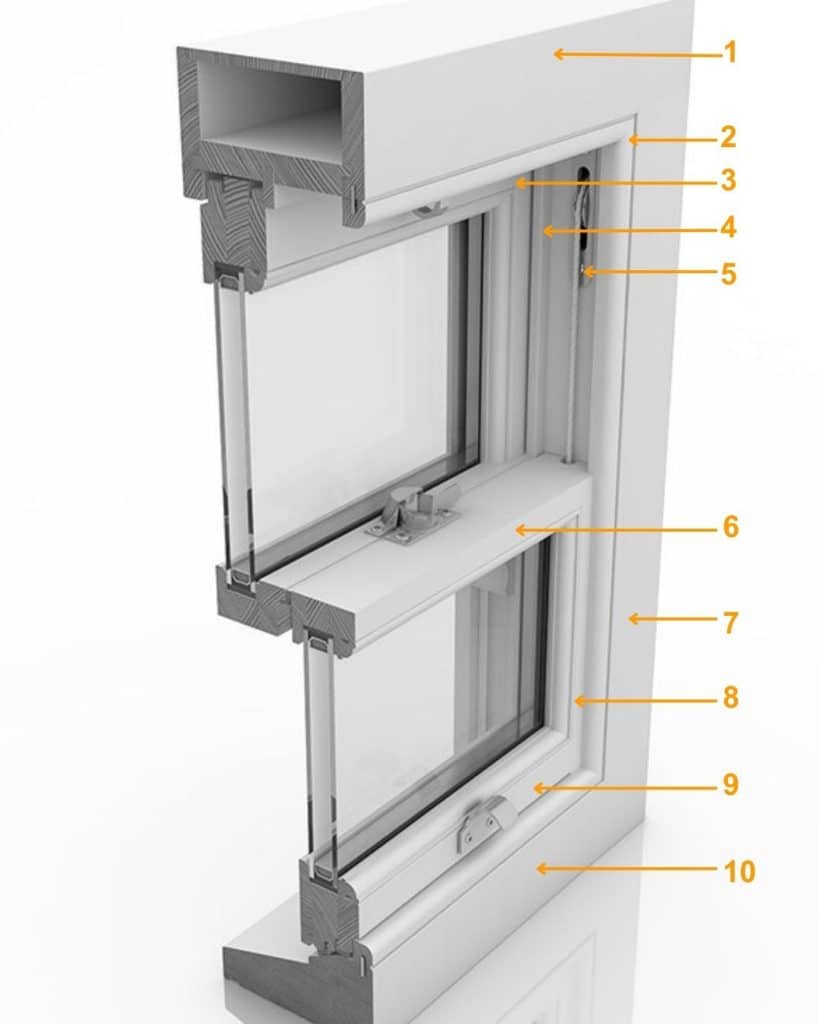

Sash window internal

Key

- 1 - Inner frame head

- 2 - Staff bead

- 3 - Sash top rail

- 4 - Parting bead

- 5 - Pulley wheel with sash cord

- 6 - Meeting rail

- 7 - Inner frame liner

- 8 - Sash stile

- 9 - Bottom rail

- 10 - Cill or sill

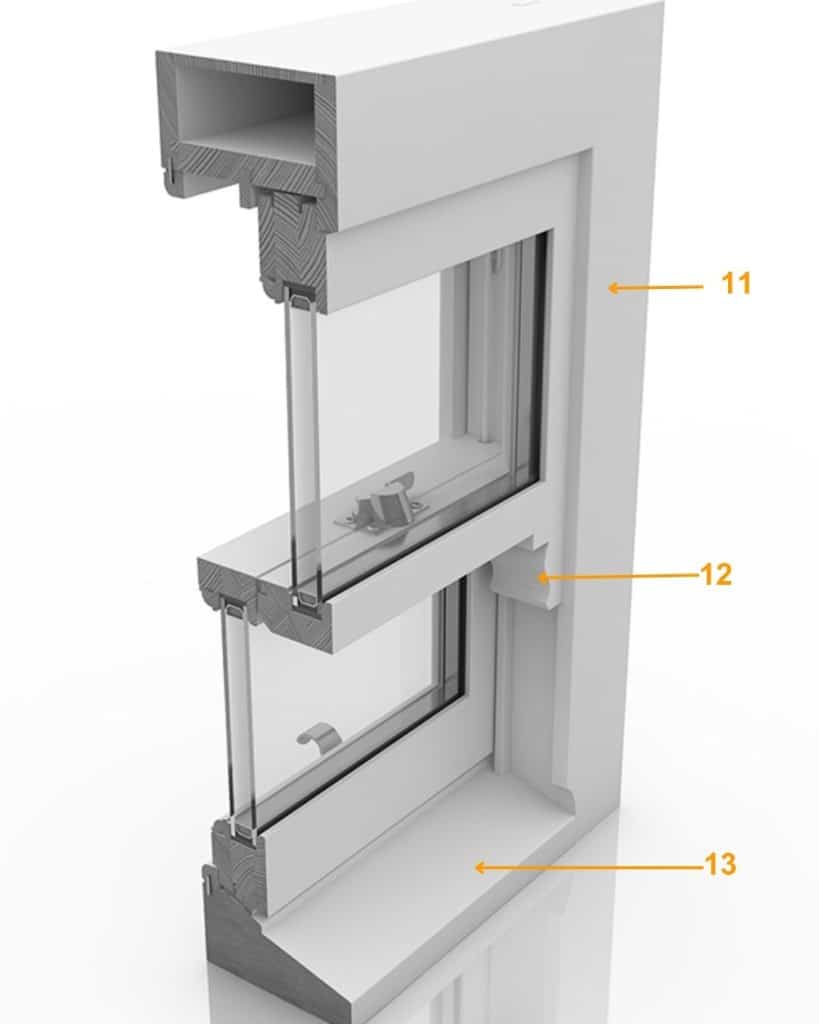

Sash window external

Key

- 11 - Outer frame liner

- 12 - Sash horn

- 13 - Cill or sill

Key

- 14 - Architrave

- 15 - Sash ring pull

- 16 - Sash stops/ restrictors

- 17 - Sash fasteners

- 18 - Glazing bar

- 19 - Sash lifts

- 20 - Bullnose window board

Need Help?

We're here to help and answer any questions you may have. Call our friendly team now for assistance.

A

Architrave

Decorative timber trim fitted around the inside of the opening to cover the junction between the wall and the sash window box. It’s installed after the window is in place and sits partly over the box and partly on the wall to give a clean framed edge.

Astragal bars

Applied bars fixed to the glass on the room side and the outside face, usually with a spacer inside the sealed unit. They give the look of multiple small panes while using one double- or vacuum-glazed unit.

B

Bead

A small moulded strip of timber. In sash windows, beads help locate glass or retain the sashes (see staff bead and parting bead).

C

Casement window

A hinged window attached to its frame with one or more hinges. The frame is fixed brick-to-brick in the opening. Unlike a box sash, a casement doesn’t need a masonry recess to house a sash box and is typically installed from the outside.

Cavity wall

External wall construction with two leaves (inner and outer) separated by a gap, usually insulated.

Cill or sill

The horizontal member at the bottom of the frame that sheds water to the outside; inside, the “window board” forms the internal shelf at the base of the opening.

Cords and weights

Traditional sash balance system. Each sash is connected by a cord over a pulley to a concealed weight inside the box. The weights counterbalance the sash for smooth opening and closing.

D

“D” handles (sash pulls)

Pull handles used to lift the bottom sash. Often paired with pole rings on the top sash so you can pull it down.

F

Flush door or window

A door or window where the face sits level with the surrounding frame, with no projecting profile.

G

Georgian bars

Bars placed inside the double-glazed unit (between the panes) to create a grid effect. Common widths are around 18–25 mm. For surface-applied bars, see astragal bars.

H

Horns (sash horns)

Shaped projections at the lower corners of the top sash stiles (and sometimes mirrored on the bottom sash). A historic reinforcement detail that also helps identify period styles.

J

Jamb

The vertical side of a door or window opening, or the vertical members of the frame itself.

K

Knots

Circular features in timber where branches once grew. They can bleed resin or show through coatings if not sealed.

Knotting (knotting solution)

A shellac-based sealer applied to timber knots before priming/painting to help prevent staining or resin bleed.

L

Lintel

A structural member above an opening (concrete, steel or timber) that carries the load of the wall above.

Lipped door or window (Stormproof)

A leaf with an edge “lip” that overlaps the frame rather than sitting fully flush.

P

Parting bead

The vertical bead that runs up the centre of the sash box and separates the two sliding sashes—top sash to the outside channel, bottom sash to the inside channel.

Plaster

Wet wall finish applied over masonry or board to create a smooth internal surface.

Plasterboard

Factory-made boards used for wall and ceiling linings, usually finished with skim plaster or paint.

Pole rings (pole eyes / finger pulls)

Small rings fitted to the top sash on the room side so a pole can be used to pull it down.

R

Rail

A horizontal member of a door or sash. In sash windows, the meeting rail is where the two sashes close together.

Reveal / recess / rebate

The inner sides and head of the window opening. A traditional box sash sits back in a masonry recess so the box is housed within the wall thickness, unlike a brick-to-brick casement. “Rebate” can refer to a stepped cut-out in timber or masonry that receives a component.

Relieving arch

An arch built above a lintel to spread load around the opening.

Render

External sand-cement (or similar) coating applied to walls.

S

Sash

The moveable glazed frame that slides within the box. A “sash window” (or sliding sash) uses two sashes in a vertical sliding arrangement.

Sash lifts

Small internal lifts/handles fitted to the bottom rail of the lower sash to raise it.

Sash stops/ sash restrictors

Stops that limit how far a sash can travel to protect finishes or improve security. They can be traditional timber stops or modern threaded security stops that can be removed or overridden when needed.

Sliding sash window

Two glazed sashes that slide vertically within a box frame. The sashes are balanced by weights and cords or by spiral balances.

Sill or cill

The horizontal member at the bottom of the frame that sheds water to the outside; inside, the “window board” forms the internal shelf at the base of the opening.

Skim

A thin finishing coat of plaster applied to achieve a smooth surface ready for painting.

Skirting

Board fixed at the junction of wall and floor to cover the gap and protect the wall.

Spring / spiral balance

An alternative to weights and cords. Each sash is supported by a spring-loaded spiral mechanism housed in a tube, connected to the sash at one end and the frame at the other.

Staff bead

The inner bead that retains the sashes within the box frame. Often carries the draught seal. Typically one on each vertical and one at the head and sill line on the room side.

T

Travel restrictors

Devices that limit opening, commonly to around 100 mm, for safety or compliance. Some designs can be released for cleaning or egress where required.

Trickle vents

Small controllable openings—usually in the head of the frame or sash—that allow background ventilation. May be required by Building Regulations depending on the project.

U

U-value

A measure of heat transfer through a building element. Lower numbers mean less heat loss and better thermal performance.

W

Warm-edge spacer

The spacer bar around the perimeter of a sealed unit made from low-conductivity material. Reduces heat loss and the chance of condensation forming at the glass edge compared with older aluminium spacers.